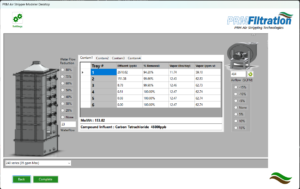

Air Stripper Modeler

PRM is proud to offer an online modeler as well as a new, innovative offline modeler software with exclusive features. View the online modeler or download a free copy of the software today!

Typical Features

- Skid or Trailer Mounted

- Up to 99.99% Efficiency

- Stainless Steel Welded Construction

- Stackable Trays with Tension rods for a Tight Seal

- Field Replaceable Gaskets

- Access Ports on Each Tray for Inspections

- Inlet Mist Eliminator

- Blowers with Premium Efficiency Motors Rated for Class 1, Div. 2 Locations

- Intrinsically-Safe Low Pressure Switch

- Manual Sump Drain Valve

- 3 Float Stem Mounted in a 2” Clear PVC Sight Tube for Pump and Alarm Controls

- Ball Valves on the Inlet and Discharge

Options:

- Variable Frequency Drives for Precise Operation

- Transmitters for Sump Level Control

- UL 508A and 698A Control Panels with Wireless Telemetry for Remote Monitoring

- Off-Gas Treatment Systems

- Sequestering Systems and Hard Water Issues

- Custom Integration Into New or Existing Systems

- Installation and Field Integration Services

- Startup and Operations Services

Air Stripper Standard Packages:

- 14 Gauge Stainless Steel

- 2 – 10 HP Stripper Blower

- CT10 or 200M Pump Package

- 2 through 5 Tray Models Available

- Control Panel

- 4” Inspection/Cleaning Ports

- 1” or 2” Wide Gaskets with Simple Clamp Down Rods

- Skid Mounted (3’x’5’, 4’x6’, 4’x8’, 5’x10’)

3D Models:

PRM offers 3D renders of many of our air strippers. Click below to view our advanced renders and for more model information..

PRM Low Flow Air Strippers

The PRM Low Profile Air Strippers provide an efficient and compact product for treating contaminated water. The contaminated water stream flows over a distribution weir and along the horizontal trays. Forced air is blown through the 3/16” diameter holes in the horizontal trays and forms a froth of bubbles generating a large mass transfer surface area where the contaminants are volatilized. The clean water exits the stripper and the off-gas vapors are treated as required. The PRM Modeler is used to determine the necessary contact time, number of trays and flow rate to achieve required volatilization.

Our strippers use a unique tension rod which allows the user to properly torque the trays in place to eliminate leaks. As the stripper and gaskets age the tension rods can be tightened to seal the gaskets, extending the life of the gaskets. The proprietary PRM design reduces fouling problems often associated with air stripping. The large diameter air distribution hole combined with the turbulent flow reduces build-up of oxidized iron. Should build up occur the trays are easily removed for cleaning. Additional access ports can be added to facilitate inspection and cleaning.

Our strippers use a unique tension rod which allows the user to properly torque the trays in place to eliminate leaks. As the stripper and gaskets age the tension rods can be tightened to seal the gaskets, extending the life of the gaskets. The proprietary PRM design reduces fouling problems often associated with air stripping. The large diameter air distribution hole combined with the turbulent flow reduces build-up of oxidized iron. Should build up occur the trays are easily removed for cleaning. Additional access ports can be added to facilitate inspection and cleaning.

PRM STS Air Strippers

The efficiency of our low profile air stripper with added features for ease of use and operation!

STS Features:

STS Features:

- Transparent Front Cover: Allows for ready visual monitoring during operation.

- Standard Single Door Access: Easy air stripper maintenance and tray removal

Handles on each tray and door for user friendly functional design. - Integrated Blower: Incorporating the blower into the unit significantly reduces the overall footprint needed for the system, giving you placement flexibility during design. The integrated blower also makes repairs safer and simpler as the motor is removed directly from the stripper body without the complexity of piping which may hamper repairs.

Air Stripper Modeler

PRM has developed an online Air Stripper Modeler tool for design assistance purposes. The Air Stripper Modeler allows the user to correctly size their equipment for specific project requirements. The model is run immediately following the data entry and the results are emailed to you for project use.