Remediation Systems

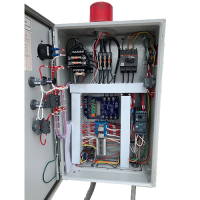

Our tried and tested remediation systems are designed and manufactured in-house. Many can be customized to your specifications or are available for lease. For addressing contaminated soil, groundwater, or vapor, a variety of equipment or combinations may be the best fit for your site.

PRM can assist in recommending the appropriate treatment solution for your application and also works with a large number of the best consulting firms nationwide.

Injects pressurized air into the soil or ground water to facilitate the removal of harmful vapors from VOC contaminated soil or ground water.

Air Sparge and Soil Vapor Extraction systems are often combined as an efficient method of removing vapor phase contaminants from soil and ground water.

PRM Low Profile Air Strippers provide an efficient and compact product for treating contaminated water.

Liquid Phase & Vapor Phase Carbon Vessels for the removal of hydrocarbons or chlorinated solvents from liquid or vapor processes.

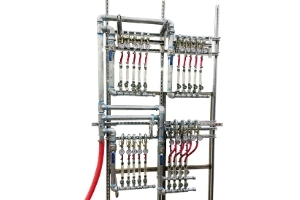

For introducing a measured sequestering agent into the water line. Chemical compounds can be used to stabilize metals in suspension.

Utilize Bernoulli’s Principal to provide high efficient fluid separation with low maintenance that can operate as a standalone system or with integrated packages.

Used in conjunction with remediation and landfill process equipment to remove unwanted moisture. Often referred to as knockout tanks.

Provide high efficient fluid separation with low maintenance that can operate as standalone systems or used with integrated packages. Designed for flow rates of 1 to 100 gpm.

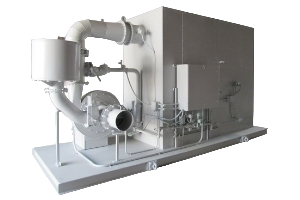

A CatOx-E electric unit offers destruction efficiencies up to 99.99% using the latest monolithic, low-temperature, catalyst modules.

For destruction of higher concentrations of VOCs using thermal mode (1400° F) or catalytic mode (700° F).

Turnkey Ozone and AOP Treatment Systems for In-Situ and Ex-Situ treatment of groundwater.

Treatment of Non-aqueous phase liquids (NAPLs) including: F.A.P. Plus ZW™, Solar NAPL, POD Skimming System, and Passive Skimming Systems.

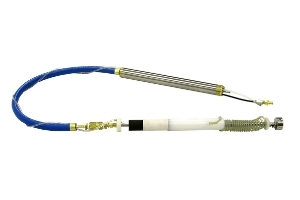

Air powered pumps used to extract ground water or total fluids at variable rates equal to the well recharge rates.

SVE systems include a blower package connect to a series of wells to apply a negative pressure in the subsurface to remove vapor phase contaminants.

Sub-Slab Depressurization (SSD) and Venting Systems for mitigation of contaminated vapors from chlorinated solvents, VOC’s, methane, radon, or petrochemicals.